Student Projects

VE/VM450

Refrigerator Air Volume Controller (Damper)

Sponsor: Li Yang, Midea

Team Members: Murray Richard, Xie Shenhao, Yang Jiaxin, Yang Ruimin, Zhu Xiaochen

Instructor: Dr. Jigang Wu

Project Video

Team Members

Team Members:

Murray Richard

Xie Shenhao

Yang Jiaxin

Yang Ruimin

Zhu Xiaochen

Team Instructor:

Prof. Jigang Wu

Project Description

Problem

One of the key components to function a fridge is a damper, which controls the airflow with the fridge. As technology is getting more advanced, consumers needs are also becoming more demanding. This project aims to provide a more precise, sustainable, powerful and innovative refrigerator damper.

Fig. 1 Current Refrigerator Damper

Concept Generation

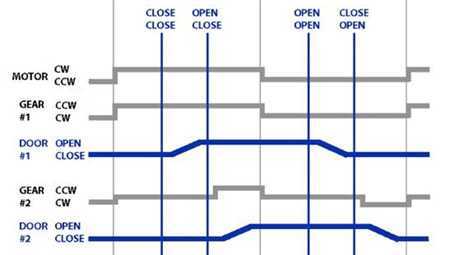

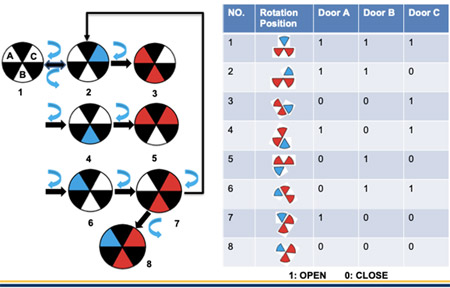

Our project aims to build a damper consisting of three independent doors, one single motor, and a simple gear transmission setup. The key to our design is to successfully implement the opening and closing of each doors independently. Our solution to this is by creating “cycles” and “delays”.

Fig. 2 Open/Close Cycle for Two Doors

Design Description

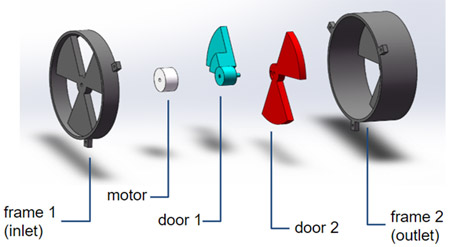

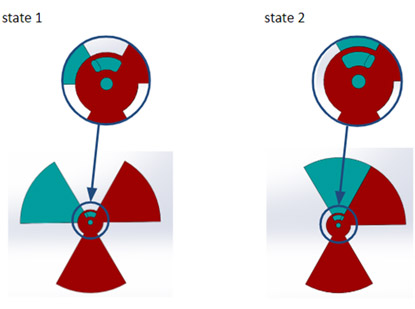

Our final design is a circular damper with an inlet frame, a motor, two rotational doors and an outlet frame as shown in Fig. 3. In order to realized the independent control of the three inlets, the two rotational doors have each been added a pin and a groove to create a delay. The delay allows the damper to enter different states where different number of doors are opened as shown in Fig. 4.

Fig 3. Exploded View of the Damper

Fig 4. Two States during Doors’ Rotation

Fig 5. All States during Doors’ Rotation

Modeling and Analysis

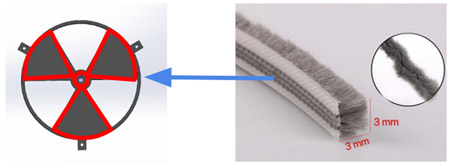

The motor used in this design is stepping motor 24BYJ48-1970. The rest of the components are made from PLA through 3D printing. It is budget friendly, convenient and is capable of functioning under a low temperature environment. Considering potential air leakage and damage done to the doors due to friction, we have decided to cover the edges of the frame with fabric sealing strips as shown in Fig. 6.

Fig 6. Spots to add Sealing Strips

Validation

Based on the details for the stepping motor 24BYJ48-1970 with a step angle of 5.625°and gear reduction ratio of 1/64, we ran several simulations and calculations. Taking in consideration the standard PLA density of 1240kg/m3, the torque needed to rotate the blades is around 0.82mN.m, whereas the motor can provide a torque up to 73.5mN.m, which is more than sufficient for this design. For any little unexpected misplacements of the doors, the sealing strips on the edges of the frame will still be able to cover most of the air so that the damper will still function as usual. As for sustainability, more tests with longer time periods will be needed to validate.

Conclusion

The project provides a multi-door and an innovative refrigerator damper. This damper can better control the temperature within a refrigerator and allow more potential functions in a fridge. The purpose of advancing technology is to provide people with better lives. Since a fridge is used by most households everyday, our damper can provide the consumers a better experience with their refrigerators on a daily basis.

Acknowledgement

Sponsor: Li Yang from Midea

Dr. Jigang Wu, Dr. Mian Li, Dr. Chengbin Ma, Dr. Chong Han, Dr. Shouhang Bo from the UM-SJTU Joint Institute;

Teaching assistants Tao Lu, Xiang Hao, Yibo Chen, Zhikang Li, and staff Allen Zhu from the UM-SJTU Joint Institute.

For more project information, please contact: [richardmurray@sjtu.edu.cn]