Student Projects

VE/VM450

Design of Refrigerator without an Auxiliary Beam

Sponsor: Yuan Chen, Midea

Team Members: Zhibo Chen, Yunqi Liu, Juhe Nie, Hanzhi Wang, Zixiao Zhang

Instructor: Dr. Jigang Wu

Project Video

Team Members

Team Members:

Zhibo Chen

Yunqi Liu

Juhe Nie

Hanzhi Wang

Zixiao Zhang

Team Instructor:

Prof. Jigang Wu

Project Description

Problem

Most multi-door refrigerators utilize a rotating mullion on the door to assist in sealing and prevent condensation. This design enables the removal of a traditional beam in the middle of refrigerators, thus allowing more room in top shelves. Nevertheless, such mullions often consist of many components, whose demanding accuracy leads to a costly manufacturing and assembling process. Moreover, its product life is lowered due to a rotation movement.

![Fig. 1 Correct (left) and wrong (right) mullion position [1]](https://www.ji.sjtu.edu.cn/wp-content/uploads/2020/07/450-13-pic01.jpg)

Fig. 1 Correct (left) and wrong (right) mullion position [1]

Concept Generation

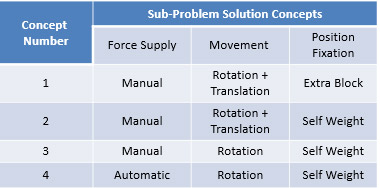

Engineering specifications and customer requirements are analyzed, and three main aspects are considered: type of force supply to move the door, type of door movement route and door fixation. Four concepts are generated, with different selections.

Table. 1 Detailed structure function

Fig. 2 Concept Diagram

Design Description

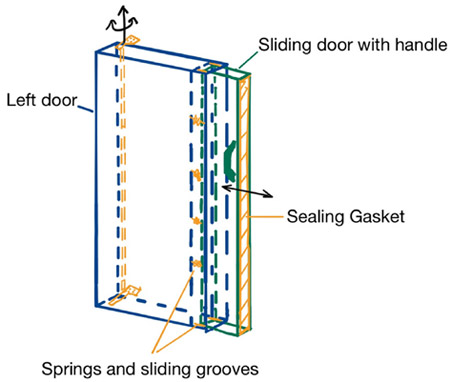

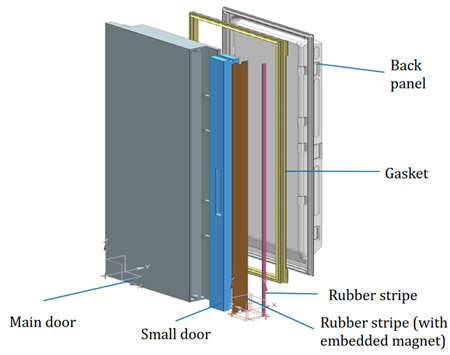

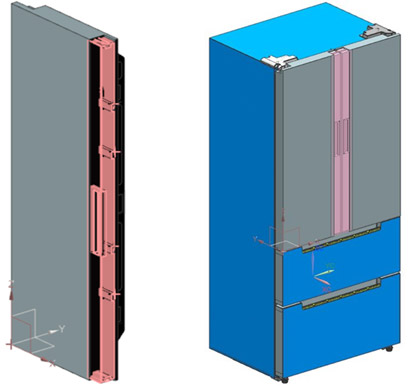

The design is comprised of a main door body and a small door that can slide in the translational direction.

Rubber stripes are attached to the middle side of the doors to assist in sealing and insulation. The small door is allowed to move in a range of +/- 0.5 cm. When the user opens the refrigerator, the small door slides into the main body, reducing the friction between rubber stripes.

Fig. 3 Explosive view of the sliding door design

Modeling and Analysis

A CAD model is built with an aim to analyze the movement during door opening and closing. The simulation result shows that the sliding of small door can be integrated into overall rotation naturally.

Fig. 4 Door assembly (left) and the top view of integrated model for movement simulation (right).

Validation

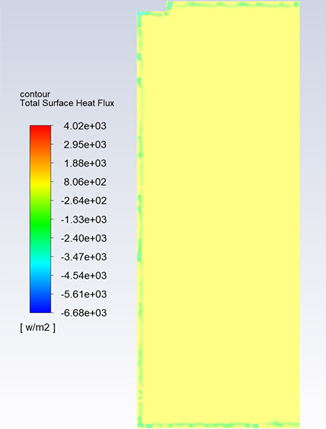

Two principle specifications are the number of components and the power consumption. The number of components can be counted accurately in Siemens NX, which is 30 components in total. As our project is primarily based on CAD , we run CFD simulations to determine whether the latter engineering specification has been met. We choose ANSYS Fluent to compute the average heat transfer rate. The average heat transfer rate per side door of our design turns out to be 54.20W while that of the traditional design is around 50W.

Conclusion

Based on the CFD results, our design of retractable doors can meet the design targets. Therefore, retractable doors can be a reasonable alternative for the rotating mullion. A 3D printed prototype is also manufactured for demonstration. Further modifications are required for industrial production.

Acknowledgement

Sponsor: Yuan Chen from Midea

Jigang Wu, Mian Li, Chengbin Ma, Chong Han, and Shouhang Bo from UM-SJTU Joint Institute.

Reference

[1] “Doors do not Seal – French Door: LG USA Support,” LG USA, 4/25/2018. [Online]. [Accessed: 5/31/2020].

Fig. 5 The distribution of heat transfer rate.