Student Projects

VE/VM450

Machine Learning Aided 1st Principle Modeling and its Application in Industrial Heat Exchanger Health Management

Sponsor: Fengcheng Sun (VP), AIMS

Team Members: Ruiqu Wang, Jiayi Chen, Marina Chen, Kerui Ma

Instructor: Prof. Shouhang Bo Mentor: Tong Zhao, AIMS

Project Video

Team Members

Team Members:

Ruiqu Wang

Jiayi Chen

Marina Chen

Kerui Ma

Instructor:

Prof. Shouhang Bo

Project Description

Problem

With time, the buildup of debris, often known as fouling, will occur on the surface of heat exchangers. Fouling can cause drop in heat transfer efficiency and in worst cases, permanent damage. This project aims to combine first principle and machine learning models to build an accurate and efficient prediction algorithm of error occurrences for one to derive a cleaning schedule from.

![Fig. 1 Fouling on Heat Exchanger[1]](https://www.ji.sjtu.edu.cn/wp-content/uploads/2020/07/450-15-pic01.jpg)

Fig. 1 Fouling on Heat Exchanger[1]

Concept Generation

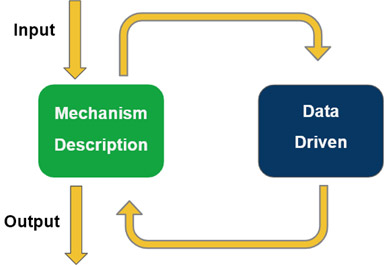

Amongst prediction models, there are two main types: first principle (mechanism), which are models based on theoretical principles, and data-driven, which are models built on data. We began with an initial naïve model and generated sub-system concepts that fulfill requirements.

Final concepts were chosen during the combinational process. Feasibility and efficiency were taken in consideration.

Fig. 2 Initial Structure

Design Description

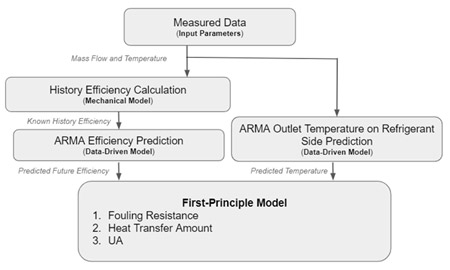

Our algorithm is broken into five sub-functions. The basic idea behind our structure is that we initially take given parameters in Matlab and summarize the current condition to be used to predict future values and then translated to respective predicted aspects with first-principle models (if needed) to describe a future state. We determine if degradation of the system occurs if the predicted values fall below predetermined values.

Fig.3 Algorithm Flow Chart

Modeling and Analysis

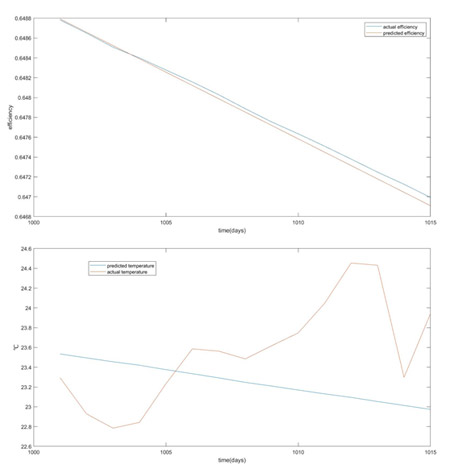

The algorithm was implemented in Matlab. Historical data is inputted and transformed into predicted values displayed in graphical form. Predictions are made for heat transfer efficiency, outlet temperature, the heat exchanger’s fouling resistance, heat transfer amount and UA.

Fig. 4 Efficiency and Outlet Temperature Prediction Graphs with Real Data Comparison

Validation

Validation Process:

We will be forming a direct prediction on a given complex real time heat exchanger Simulink model for our preset prediction interval. Afterwards, we take the predicted data and real data to calculate relative error.

Validation Results:

According to validation part, all specifications can be met.

√ # Parameters in Model >=5

√ # of Inputs Utilized >=5

√ # Input Data Points >= 2,100,000

√ Duration of Input Data >= 1000 Days

√ Number of Prediction Days >= 15

√ Temperature Error < 2𝐶^𝑜

√ means having been verified and · means to be determined.

Conclusion

We were able to construct an algorithm that can predict future conditions of a heat exchanger fairly accurately. The finalized hybrid model utilizes ARMA as its data-driven models and a variety of basic heat exchange equations compiled together as its first-principle model. Elements of focus for our algorithm was accuracy and ability to explain error occurrences.

Acknowledgement

Sponsor: Fengcheng Sun (VP) from AIMS

Tong Zhao from AIMS

Shoudhang Bo, Mian Li, Chengbin Ma, Chong Han, and Jigang Wu from SJTU Global College

Tao Lu, Xiang Hao, Yibo Chen, and Zhikang Li from SJTU Global College