Student Projects

VE/VM450

Visual Design for Sterilization and Odor Purification

Sponsor: Shufen Xia, Midea

Team Members: Gaopeng Song, Yuwen Hu, Weilun Liu, Yicheng Lu, Shuhan Wang

Instructor: Prof. Jigang Wu

Project Video

Team Members

Team Members:

Gaopeng Song,

Yuwen Hu

Weilun Liu

Yicheng Lu

Shuhan Wang

Instructor:

Prof. Jigang Wu

Project Description

Problem Statement

Although the ionization device is already able to solve the odor problem in refrigerators, as well aa keep the sterilization rate of common bacteria up to 99.9% with high efficiency, the sterilization and odor purification process cannot be well perceived and understood by users. Our project is aimed at improving the visual design of these two functions to increase user trust with better perception and high reliability.

![Fig. 1 A common visual design for sterilization and odor purification: breathing effect of light [1]](https://www.ji.sjtu.edu.cn/wp-content/uploads/2020/07/450-11-pic01.jpg)

Fig. 1 A common visual design for sterilization and odor purification: breathing effect of light [1]

Concept Generation

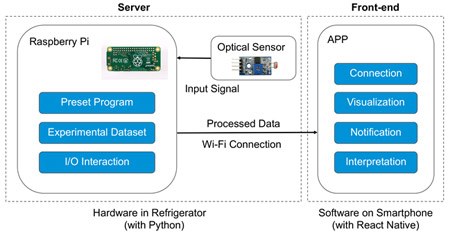

Visualizing the sterilization and odor purification progress in an App user interface is our chosen design concept due to its high accuracy, accessibility, intuitiveness, feasibility as well as low costs. Considering the confidentiality regulations of Midea company, a demo-used backend is constructed to send data to the App on the smartphone with Raspberry Pi as the MCU, simulating the hardware part in the real refrigerator that sends data of sterilization and odor purification process and supports the connection to the smartphone.

Fig. 2 Concept Diagram

Design Description

Our project focuses on the user interface design as the front-end of the APP. Four main features — the progress bubble, remaining completion time, finish notification and the principle explanation page — are included, among which the bubble works as the core feature to give users a whole precise perception of the sterilization and odor purification progress. Users are able to choose whether to turn on or off the notification when the progress is finished.

Fig. 3 The user interface

Modeling and Analysis

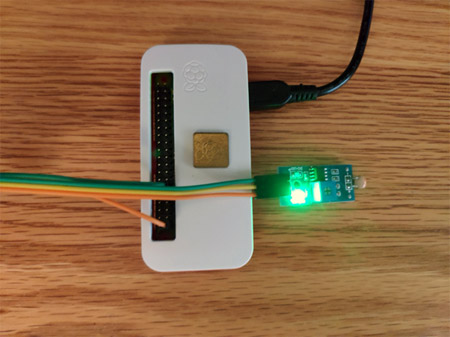

The Raspberry Pi receives the digital output of the optical sensor as the modeling of the signal for opening and closing of the refrigerator door. The progress of sterilization and odor purification is then processed according to experimental dataset.

Fig. 4 Raspberry Pi with optical sens

Validation

Validation Process:

For the digital output of the optical sensor, we set up an experimental program and manually control the light condition to verify the accuracy and reliability of the output data.

For frontend visualization, we build a series of virtual data as the received info to see the UI of the APP.

For the connection between the smartphone and Raspberry Pi, we transmit different kinds of data to test the speed and completeness.

For user evaluation, we establish a questionnaire for feedback of public.

Some other specifications can also be verified using easy experiments.

Validation Results:

According to validation part, most specifications can be met.

√ Connection time<=30s

√ Accuracy of sensor>=99%

√ Operating temperature>=—20℃

√ Cost<=300RMB

• Synchronize time<=1s

√ means verified and · means to be determined.

Conclusion

COur UI design of the APP serves as the visualization for the progress of sterilization and odor purification of the refrigerator, which greatly increases the user trust with better perception and high reliability of the two functions. This project can be easily transplanted, extending the potential possibilities of the diversity functions lying in the refrigerators.

Acknowledgement

Sponsor: Shufen Xia from Midea

Mian Li and Chengbin Ma from UM-SJTU Joint Institute

Chong Han, Jigang Wu and Shouhang Bo from UM-SJTU Joint Institute